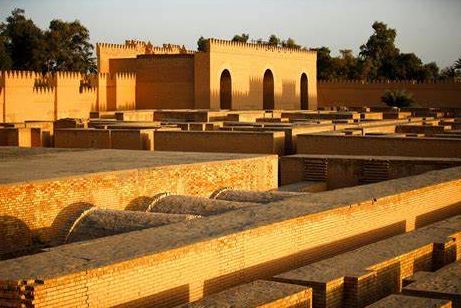

RUINS OF BABYLON: At the temple of Ninmakh, the Sumerian mother goddess, Iraqi archaeologists are using 7,000-year-old techniques to protect the monument, and the rest of the ancient city of Babylon, from salt seeping into its heart and destroying it from within.

With carefully made desalinated mudbricks, they are repairing the ruins of the UNESCO World Heritage site, which are being corroded by the intrusion of increasingly salty groundwater — a problem linked to prolonged droughts and soil erosion in climate-vulnerable Iraq.

“Salty groundwater is our greatest enemy,” said Ammar Al-Taee, an archaeologist with the Iraqi State Board of Antiquities who oversees the project and calls himself wryly “the guardian of Babylon.”

The ancient Mesopotamian city on the Euphrates River was once the center of a sprawling empire, renowned for its towers and mudbrick temples. Its hanging gardens, built about 2,600 years ago, were one of the seven ancient wonders of the world.

Problems such as salt intrusion, extreme temperatures, flooding and soil erosion linked in part to climate change are threatening heritage sites in Iraq and around the world, from indigenous rock art in Australia to Bangladesh’s 15th century “Mosque City.”

Al-Taee and his team learned the painstaking, months-long process of making special low-salt mudbricks from a local artisan who had inherited the age-old technique from his father, and they produced their first batch for repairs this year.

First, the experts scoured the ground for more than a week before finding soil with tolerable salt levels. Even then, the soil had to be “washed” to make it even less salty, Al-Taee said. Next, the mud was mixed with sand, grit, straw and water, shaped into a large circle and left to ferment for a month, a process that drives the remaining salt to the edge of the mix, producing a white, crystalline fringe.

After scraping away the unwanted salty crust, the remaining sludge was then shaped into bricks, which were laid out on plaited reed mats woven by local women’s cooperatives, giving the blocks a distinctive pattern.

The whole process reduces the amount of salt in new mudbricks by almost three quarters, Al-Taee said.

Once they had been stacked in the shade of a tree for a couple of days to air, the bricks were spread out in the sun to bake for a month before being ready for use.

Al-Taee’s worst enemy, salt, is evident everywhere.

Despite the magnitude of the problem, Al-Taee said he receives no support from the Iraqi government. His current projects depend entirely on foreign funding.

“The lack of support and investment from the government is our biggest challenge,” he said, pointing to the high cost of basic supplies — even clean water, which has become more expensive in drought-plagued Iraq.